DRY ICE BLASTING IS CLEAN, SAFE, AND IDEAL FOR VARIOUS PHILIPPINE INDUSTRIES.

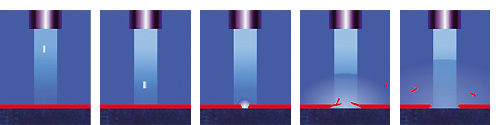

Dry ice blasting is also known as dry ice cleaning and cryogenic cleaning here in the Philippines. The process is similar to sand blasting where a medium is accelerated in a pressurized air stream to impact a surface to be cleaned. That is where the similarity ends though.

Instead of using hard, abrasive media to grind on a surface (and damage it), dry ice blasting uses soft dry ice (accelerated to supersonic speeds) to lift the undesirable contaminant off the underlying substrate.

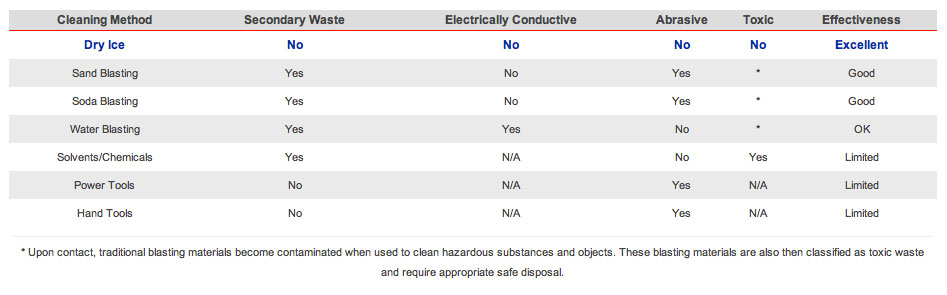

DRY ICE BLASTING HAS MANY UNIQUE AND SUPERIOR BENEFITS OVER TRADITIONAL CLEANING MEDIA.

Dry ice blasting:

1. is a non-abrasive, non-flammable and non-conductive cleaning method

2. is environmentally-responsible and contains no secondary contaminants such as solvents or grit media

3. is clean and approved for use in the food industry

4. allows most items to be cleaned in place without time-consuming disassembly

5. can be used without damaging active electrical or mechanical parts or creating fire hazards

6. can be used to remove production residue, release agents, contaminants, paints, oils and biofilms

7. can be as gentle as dusting smoke damage from books or as aggressive as removing weld slag from tooling

8. can be used for many general cleaning applications

Dry ice blasting uses compressed air to accelerate dry ice pellets to a high velocity. A compressed air supply of 80 PSI/50 scfm can be used in this process.

Dry ice pellets are made from non-toxic, food-grade carbon dioxide in the Philippines.